A ProMash Recipe Report

| BJCP Style and Style Guidelines |

| Min OG: | 1.056 | Max OG: | 1.075 | |

| Min IBU: | 40 | Max IBU: | 72 | |

| Min Clr: | 6 | Max Clr: | 15 | Color in SRM, Lovibond |

| Recipe Specifics |

| Batch Size (Gal): | 11.00 | Wort Size (Gal): | 11.00 |

| Total Grain (Lbs): | 36.50 | ||

| Anticipated OG: | 1.064 | Plato: | 15.65 |

| Anticipated SRM: | 6.6 | ||

| Anticipated IBU: | 35.8 | ||

| Brewhouse Efficiency: | 48 | % | |

| Wort Boil Time: | 90 | Minutes |

| Pre-Boil Amounts |

| Evaporation Rate: | 15.00 | Percent Per Hour | |

| Pre-Boil Wort Size: | 14.19 | Gal | |

| Pre-Boil Gravity: | 1.050 | SG | 12.28 Plato |

| Formulas Used |

Final Gravity Calculation Based on Points.

Hard Value of Sucrose applied. Value for recipe: 46.2100 ppppg

% Yield Type used in Gravity Prediction: Fine Grind Dry Basis.

Color Formula Used: Morey

Hop IBU Formula Used: Rager

Additional Utilization Used For Plug Hops: 2 %

Additional Utilization Used For Pellet Hops: 10 %

| Grain/Extract/Sugar |

| % | Amount | Name | Origin | Potential | SRM |

| 41.1 | 15.00 lbs. | Pale Malt(2-row) | America | 1.036 | 2 |

| 41.1 | 15.00 lbs. | Pale Malt(2-row) | Great Britain | 1.038 | 3 |

| 5.5 | 2.00 lbs. | Weyermann Vienna | Germany | 1.038 | 4 |

| 5.5 | 2.00 lbs. | Turbinado Sugar | Generic | 1.046 | 0 |

| 2.7 | 1.00 lbs. | Crystal 15L | America | 1.035 | 15 |

| 2.7 | 1.00 lbs. | Cara-Pils Dextrine Malt | 1.033 | 2 | |

| 1.4 | 0.50 lbs. | Wheat Malt | America | 1.038 | 2 |

Potential represented as SG per pound per gallon.

| Hops |

| Amount | Name | Form | Alpha | IBU | Boil Time |

| 1.50 oz. | Horizon | Pellet | 11.40 | 35.8 | 60 min |

| Yeast |

| Water Profile |

| Profile: | Marin County CA |

| Profile known for: | |

| Calcium(Ca): | 12.0 ppm |

| Magnesium(Mg): | 10.0 ppm |

| Sodium(Na): | 15.0 ppm |

| Sulfate(SO4): | 17.0 ppm |

| Chloride(Cl): | 13.0 ppm |

| biCarbonate(HCO3): | 74.0 ppm |

| pH: | 8.31 |

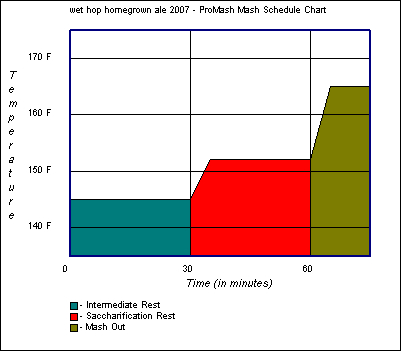

| Mash Schedule |

| Mash Type: | Multi Step | |

| Grain Lbs: | 34.50 | |

| Water Qts: | 41.40 | Before Additional Infusions |

| Water Gal: | 10.35 | Before Additional Infusions |

| Qts Water Per Lbs Grain: | 1.20 | Before Additional Infusions |

| Rest | Temp | Time |

| Acid Rest: | 0 | 0 Min |

| Protein Rest: | 0 | 0 Min |

| Intermediate Rest: | 145 | 30 Min |

| Saccharification Rest: | 152 | 30 Min |

| Mash-out Rest: | 165 | 15 Min |

| Sparge: | 0 | 0 Min |

Total Mash Volume Gal: 13.11 - Dough-In Infusion Only

All temperature measurements are degrees Fahrenheit.

| Notes |

|

mash water salts 1 tbsp buffer 5.2 3.6 grams chalk (.3 grams per gallon) 4.8 grams gypsum (.4 grams per gallon) * the goal is about 50 ppm of calcium for yeast growth whirlfloc at 30 minutes wyeast nutrient at 10 minutes Mash Schedule 1.2 quarts/gallon 145 beta amalayze rest for 30 minutes 152 alpha amalyze rest for 30 minutes 165F mash out for 15 minutes 48% efficiency = very low because this is using the no-sparge method. ** Remember to add 2 gallons to the Polarware mash tun to make up for the floor space below the false bottom Hop schedule includes store purchased hops only. 4LB of fresh, homegrown hops were added starting at 15 minutes, 4oz each minute up until flame out, with 2 oz. added at flame out. Homegrown hops were a mix of Chinook, Nugget, Centennial and Cascade. fermentation procedure: 10 gallon conical with 2liter WLP001 yeast starter. ferment at 66-68F, 6-7 days maximum, diacetyl rest at 70F for 24 hours drop the temperature to 52F for 2 days to pull the yeast out set the max temperature back to 68F and start the 12 day dry hopping at this point, letting the temperature slowly creep back up to 68F over a few days. Leave it at 68F for the bulk of the dry hopping regiment. 8oz. of wet hops from the same crop added for dry hopping. Drop it down to 33F for transfer 11 days into the dry hopping, so do about 1 day of cold conditioning before transferring it to the serving tank. Very gently stir the dry hopping additions to keep the hops in suspension |

Generated with ProMash Brewing Software